In February of 2019, following new scientific evidence from the International Agency for Research on Cancer, the HSE issued a safety alert regarding welding fume. The evidence indicated that exposure to all welding fume (including mild steel), could lead to lung cancer and possibly even kidney cancer. The alert was aimed at anyone and everyone that may undertake or oversee welding activities across all industry types.

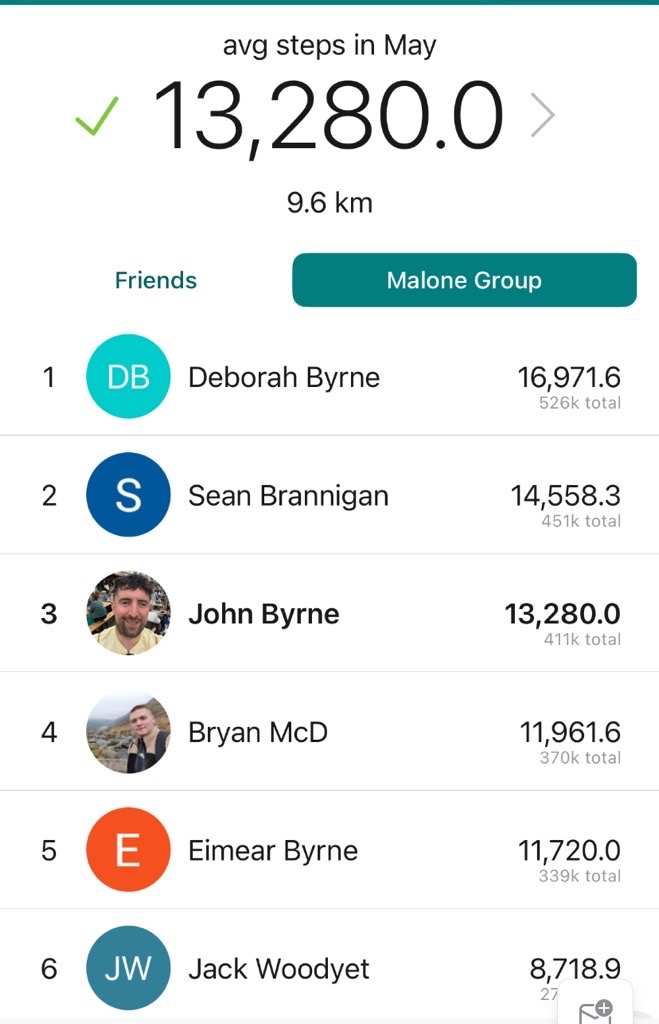

Here at Malone Group, welding activities are often undertaken on the projects that we oversee across a multitude of food, beverage and pharmaceutical sites. We have therefore made it a priority to ensure compliance with the HSE’s new expectations for controlling welding fume, as well as continuing to ensure we are controlling the other inherent risks associated with the activity, namely fire, through our electronic hot-works permit.

We are currently providing an EHS Advisor to the Principal Contractor on a multi-million-pound development at a major brewery in the UK. The project will see the installation of eight new fermentation vessels, and therefore fabrication and welding activities run through the heart of the project. Even though the bulk of this activity is taking place outside, general ventilation is no longer recognised as an adequate control.

Where welding activity cannot be avoided by other joining methods, engineering controls take priority in the form of Local Exhaust Ventilation (LEV) systems to extract the fume away from the welder at source. A LEV system would not be very effective outside on a windy winter morning however…

So, we then move to the next step in the hierarchy, as per the HSE’s new guidance on controlling welding fume. This comes in the form of respiratory protective equipment (RPE). Due to the long duration of the works, all welders on site utilise battery-powered air-fed protective equipment, with a minimum assigned protection factor of 20 (APF20).

If you would like more information on the new requirements, please refer to the COSHH advice sheets for welding, cutting and surface preparation on the HSE website.

For more information on Malone Group’s Safety Management services, contact our Regional Safety Manager, Dan Clapcott at daniel.clapcott@malonegroup.com.