- About

- Services

Collaborative planning and execution

Working hand-in-hand with your team, Malone Group assists in planning and executing your project from its conceptual stage to commissioning. Our goal is to ensure timely completion within budget, prioritizing safety compliance throughout the process.

Comprehensive range of design services

Your capital project will benefit from our comprehensive range of engineering design services, including feasibility studies, outline designs, budget costing, detail designs/full specifications and tendering packages.

Delivering Zero Harm in all environments

Our team provides class leading safety management services, driven by the close integration between our safety and engineering departments.

Using less resources for the same output without compromising on quality

Our engineers design solutions that minimise energy and water consumption using both established technologies and and new innovative solutions.

Simplified, practical and cost effective solutions

We automate processes to enable data collection, as a key step towards digital transformation. Employing a range of competencies across the group we generate practical, budget conscious transformation roadmaps that we can then implement. This is a key step towards being a factory of the future or even just a better manufacturing space for today.

Connecting the parts to work together automatically

Automating production and process environments provides many benefits. Utilizing the experience and expertise of our teams, we manage the delivery of automation solutions; from obsolescence assessments to system design (PLC, SCADA, HMI etc.), integration to commissioning.

- Capabilities

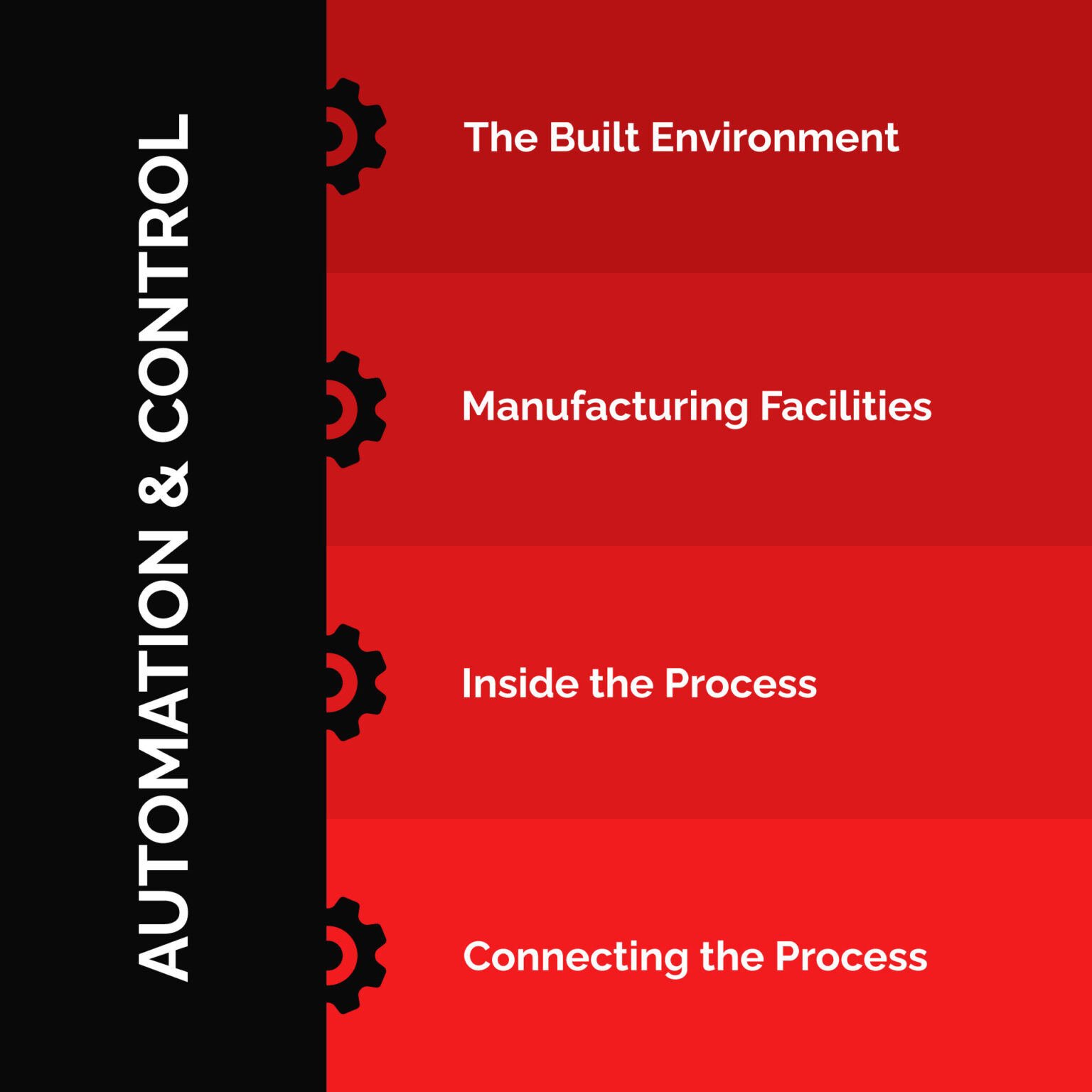

Optimised for performance, safety, and sustainability

The Built Environment encompasses commercial, retail, medical, and educational buildings and manufacturing sites It’s where, we as engineers, bring life to architectural concepts, designing systems to make the spaces functional, workable and livable. Our practicality and expertise shines brightly, crafting environments that resonate with efficiency, sustainability, and innovation.

Engineering marvels meet practical application

Manufacturing Facilities are not just buildings, they are the cradle of innovation, where engineering marvels meet practical application. We appreciate that each facility is a unique entity, a bespoke blend of technology, human skill, and process. This understanding is the bedrock upon which we offer our services, ensuring that each customer’s facility is not only built to last but also to evolve.

Mastering the core operations that drive productivity

Inside the Process delves deep into the heart of manufacturing and production processes, uncovering the layers and intricacies that make industries tick. We stand as a guiding light in this complex domain, wielding expertise and innovation to optimize and enhance every step.

It is bridging the gaps between isolated processes

Connecting the Process is a crucial aspect that harmonises the various segments of production, operations, and management to create a seamless flow. This capability is about bridging the gaps between isolated processes, ensuring that every step from inception to delivery is interconnected and efficient. In the vast tapestry of industry, Connecting the Process serves as the thread that weaves through each operation, enhancing communication, data flow, and operational synergy. Malone Group, with its profound expertise and innovative solutions, is at the forefront of making these connections tangible and effective.

Engineering marvels meet practical application

Welcome to our forward-thinking approach to embedding sustainability at the heart of today’s operations and projects. In a world where the environment and sustainability are not just concerns but imperatives, A Sustainable Now represents our commitment to creating solutions that meet the needs of the present without compromising the ability of future generations to meet their own needs. This vision encompasses a broad spectrum of practices, from reducing carbon footprints and enhancing energy efficiency to promoting renewable resources and sustainable development.

Enhancing precision, efficiency, and engagement

Looking to the Future is a concrete approach to integrating advanced technologies into the fabric of engineering, design, and project management. This forward-looking vision encompasses Augmented Reality (AR), Virtual Reality (VR), and 3D Modeling, technologies that are revolutionizing the way we visualize, interact with, and understand complex processes and environments. Malone Group is at the forefront of this revolution, leveraging these technologies to provide innovative solutions that enhance precision, efficiency, and engagement in a wide range of industries.

- Projects

- Careers

Obsolescence

Efficient, Safe, Full-Service

Modernisation and obsolescence to deliver more efficient production operations

Malone Group provides legacy systems modernisation and obsolescence management services to ensure your mission-critical production processes remain fully operational with minimum downtime. This is one of the greatest challenges and concerns in manufacturing and process industries. We work collaboratively with your team to address the obsolescence management challenge in a way that delivers a smooth transition, modernises the production/ operating systems offering greater efficiency and data insights while solving some of the challenges of the past.

Obsolescence in legacy systems typically relates to PLC hardware, SCADA and HMI equipment, to control panel equipment, cabling and instrumentation and control devices. Obsolescence problems generally lead to excessive downtime, as parts are become unavailable. This can really impact the productivity, efficiency and lead times for your business. Malone Group manages this whole process for you to manage these risks by identifying potential issues, planning replacements and implementing changes.

Understanding Your Unique Needs

Complete Automation Solutions

Our focus is not on upgrading/migrating the legacy equipment and systems with new technology but to use this opportunity to look at the bigger picture and resolve the nagging unaddressed issues of the past and transform the overall operations. Our services begin with site wide control systems survey to document the installed base with obsolescence risk assessments supported by migration plans for key equipment.

This involves the replacement of legacy systems with detailed installation, migration and commissioning plans to minimise disruption. Our structured approach ensures that the critical equipment is identified and areas of greater risk are prioritised, and a plan is in place to mitigate that. This avoids downtime and manages legacy systems modernisation and obsolescence to deliver more efficient production operations.

We specialise in modernising legacy systems and managing obsolescence to keep mission-critical production processes running smoothly with minimal downtime, addressing one of the major challenges in the manufacturing and process industries.

We work closely with your team to tackle obsolescence management challenges, ensuring a seamless transition to modernized production and operating systems that offer enhanced efficiency and deeper data insights, while resolving past issues.

Our services address obsolescence in critical areas including PLC hardware, SCADA and HMI equipment, control panel components, cabling, and instrumentation and control devices, thereby preventing excessive downtime due to unavailable parts.

Through identifying potential obsolescence issues, planning for replacements, and implementing necessary changes, Malone Group manages the entire process to mitigate risks and enhance productivity, efficiency, and lead times for your business.

Beyond simply upgrading or migrating legacy equipment, we seize the opportunity to address long-standing issues, offering a comprehensive review and transformation of overall operations with a site-wide control systems survey and obsolescence risk assessments.

Our approach includes detailed installation, migration, and commissioning plans for legacy system replacement, prioritising critical equipment and high-risk areas to mitigate downtime, ensuring a smooth transition to more efficient production operations.

Related Capabilities

Capabilities are the cornerstone of our expertise

Automation & Control services encompass a comprehensive suite tailored to modernize and optimize industrial processes. With deep expertise across both contemporary and legacy platforms such as B&R, Omron, Mitsubishi, GEM, Siemens, and Rockwell, we ensure seamless specification, installation, and networking integration right at the plant floor. Our approach integrates business systems for enhanced reporting and scheduling, backed by the expertise of our in-house process engineers to deliver efficient plant control and vital production information.

We manage complete automation solutions from design to commissioning, including skid systems like CIPs, providing end-to-end support for a ready-to-operate system. Our services extend to include FAT, SAT, and performance trials for commissioning support, real-time remote access support for immediate issue resolution, and a broad portfolio covering everything from SCADA systems and process control to system integration and legacy upgrades. This comprehensive offering is designed to streamline operations, reduce downtime, and ensure a rapid, secure transition into automated efficiencies.

By integrating cutting-edge technology, eco-friendly materials, and green spaces, we strive to enhance community well-being, reduce environmental impact, and build spaces that are safe, accessible, and geared towards the future.

Comprehensive support across the lifecycle of manufacturing projects, from initial design through to execution and maintenance, thereby driving operational improvements and fostering innovation within customer operations.

By closely examining and understanding every aspect of the production line, we identify opportunities for improvement, integrating advanced automation, data analytics, and process re-engineering to drive performance and reduce costs.

By implementing advanced data analytics, AI, and IoT solutions, our team enhances connectivity across processes, improving decision-making, productivity, and operational agility, ultimately delivering a more streamlined manufacturing or built environment.

Automation & Control Services

Frequently Asked Questions

If you have any further questions or require additional information, please don’t hesitate to contact us. We’re here to assist you.

Malone Group's automation and control services are designed to streamline and optimize industrial processes through the implementation of cutting-edge technologies. Our services range from designing and implementing bespoke automation solutions, PLC (Programmable Logic Controller) programming, SCADA (Supervisory Control and Data Acquisition) systems, to integrating advanced control systems that enhance efficiency, productivity, and safety. We focus on delivering solutions that are tailored to meet the unique needs of our clients' operations.

By leveraging our automation and control services, clients can expect significant improvements in their manufacturing processes, including increased operational efficiency, reduced production costs, enhanced product quality, and minimized downtime. Our solutions are designed to optimize resource use, automate repetitive tasks, and provide real-time data for better decision-making, leading to overall process improvement and competitive advantage.

Absolutely. We understand that each industry and client has unique requirements and challenges. Our team works closely with clients to understand their specific needs, designing and implementing automation solutions that are fully customized to align with their operational goals. Whether it's food and beverage, pharmaceutical, manufacturing, or any other sector, we tailor our solutions to fit the particular nuances of each industry.

Data is at the heart of our automation and control services. We implement systems that not only automate processes but also collect and analyze data to provide actionable insights. This enables continuous process improvement, predictive maintenance, and more informed decision-making. Our aim is to transform data into a strategic asset for our clients, driving efficiency and innovation.

Our team specializes in integrating new automation and control systems with existing infrastructure in a seamless manner. We conduct thorough analyses to understand the current setup and design solutions that complement and enhance the existing processes. Our expertise ensures that the transition is smooth, with minimal disruption to ongoing operations, maintaining continuity and maximizing the value of both new and existing systems.

What sets Malone Group apart is our comprehensive approach that combines technical excellence with a deep understanding of our clients' business goals. Our team of engineers and specialists is dedicated to delivering not just solutions but also strategic advantages that make our clients' operations more efficient, resilient, and competitive. We stay at the forefront of technological advancements to ensure our clients benefit from the latest innovations in automation and control, tailored to their specific operational needs.