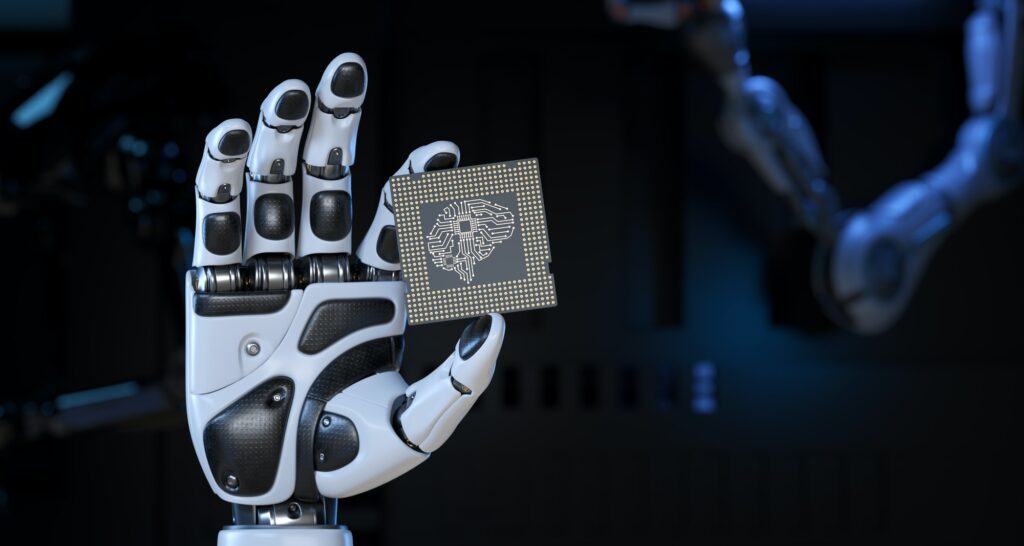

The project involved the specification and installation of an automated distribution centre for order building, which had previously been all manual. Robots depalletized full skids of one SKU, which were then conveyed to their own separate storage lane of 360 possibilities. Mixed SKU pallet orders were built by conveying exactly what SKUs and amounts were needed from the lanes to the palletizers, and a pallet built in the optimal layer design.

Automated Distribution Center

Efficient, Safe, Full-Service

- Location: Canada

- Sector: Beverage

- Service: Business case development, Detailed design, Feasibility study or FED/ FEED, Project support office, System qualification and security

Project Benefits

Diligent project

management, deficiency list management, strong change management

results by in and operator buy-in.